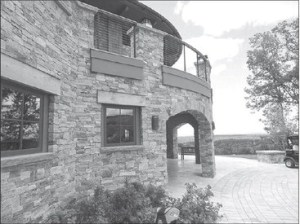

BETHEL — More than a decade after the Bethel Furniture Stock mill closed its wood products operation in the face of foreign competition and high energy prices, a different kind of manufacturing business has moved into the mill buildings on West Bethel Road.

Masonry Mill will soon be cutting and sawing locally sourced natural stone, producing inch-thick stone veneer for interior and exterior use on buildings, foundations, chimneys, fireplaces and other architectural features.

“It’s an amazing natural building material, made from local stone and shipped worldwide,” Masonry Mill founder Ben Croteau said.

Croteau is not new to the natural stone veneer business. Before buying the mill, he served as chief operations officer for Stoneyard.com, a third-generation family company that has been milling natural stone veneer in Littleton, Mass., for over 25 years.

Stoneyard.com employs 75 people in a thriving business that Croteau helped build. The company produces real stone veneer in five shapes and six natural colors.

The milled veneer weighs less than 14 pounds per square foot and can be applied to the surfaces of new construction or renovation inside or out. Specially milled 90-degree corners give it the appearance of full-thickness stone in applications, without the additional weight.

The Masonry Mill in Bethel will use stone from farmers, landowners and quarries and will supply customers nationwide, Croteau said.

After many years in the family business, he is eager to take on the challenges and responsibilities of running a mill on his own.

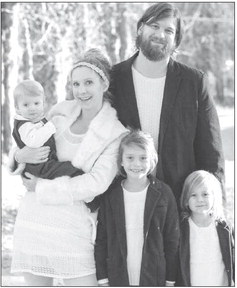

He is looking forward to relocating his family, which includes his wife, Lakin, and their three sons, who are 8, 6, and 1, to the Bethel area from their current home in New Ipswich, N.H.

“The boys are very excited,” he said, adding he is familiar with Bethel and has family roots in the area.

“This mill is in a great spot, and it’s a great opportunity,” Croteau said of the manufacturing plant that has been largely empty since Bethel Furniture Stock closed its doors.

The wood mill’s workforce had dwindled from more than 90 employees to about 30 at the time of the 2005 closure.

“The first thing to go from the facility was the boiler, so not much happened at the mill after that,” said former Bethel Furniture Stock employee Eric Boyle-Wight.

A timber-frame business was located in one of the buildings for several years, and Kennebec Lumber maintained a log concentration yard on the property until recently, he said.

Within the past few years, former owner Leon Favreau sold the mill to lumber importer Rory Wood, owner of Rare Woods USA in Mexico, Maine. Wood used it to warehouse the lumber he imports from all over the world, but nothing was done to revitalize the mill until Croteau bought the property late last year.

“I got started right after purchase on turning the bending shed into a saw shop, and the old saw shops will be buildings that the rock shaping, packaging, and cleaning/ inspection takes place in,” Croteau said.

He said a new heating system to replace the old boiler is in the works, and added that the stone veneer business does not require steam from a boiler for processing materials like Favreau’s wood furniture business did.

Croteau said he is excited about bringing a manufacturing business back to Bethel.

“I didn’t want to see this place rot to the ground,” he said.

Water and diamonds are used to turn local stone into a variety of Masonry Mill products, Croteau said. Diamond cutting blades in the specially designed stone saws are continually cooled with running water during the manufacturing process.

Eventually, he predicted, his mill could have a sizable impact on the local economy.

Although he plans to start small, working with one or two employees, once the mill is fully operational, he will need workers to perform a variety of tasks, including cutting, splitting, and packaging the stone veneer products, as well as sourcing the raw stone from which they are manufactured.

“It’s very exciting to manufacture something, to make a good product. The main things I need are great workers and materials,” said Croteau, who believes he will find plenty of both in the Bethel area.

Comments are no longer available on this story